Great Gifts

Our products make a great gift for all kinds of occasions:

Birthdays

Graduations

Holidays

New Jobs

Promotions

Anniversaries

Bosses Day

Executive Gifts

How a Handcrafted Pen is Made

What goes into producing a high quality handmade product such as one of our handcrafted pens or pencils?

Handmade Pen Creation

Great Gifts

Our products make a great gift for all kinds of occasions:

Birthdays

Graduations

Holidays

New Jobs

Promotions

Anniversaries

Bosses Day

Executive Gifts

Step 1: Select the Material

Our pen bodies are hand turned from exotic woods, hard woods, acrylic, and true stone materials from all over the world to create the pen blank. Sometimes we take different species of wood cut them and glue them together to create pen blank that contains a pattern. We will also create a custom product out of a body material a customer supplies for example a small piece of drift wood found on vacation or a piece of board from their kids tree house to create a unique gift.

Step 2: Cut the Material to Size

Depending on the style of pen, the pen blank needs to be between 5/8 and ¾ high and wide to make a pen and for most pens at least 5.5 inches long. If the blank is larger we cut it down to start with a blank that is at least that size. If we are combining different species of wood we will cut them smaller and then glue the different woods together to get the blank back to an appropriate size. If the pen requires two sections we will cut the pen blank at the appropriate length for each required section of the pen.

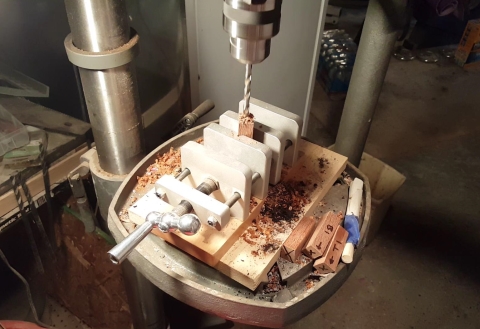

Step 3: Drill the Blanks

A hole must be drilled through the center of the blank. Depending on the blank’s design or pattern there is very little room for error when drilling and it should be directly through the center of the blank. We have 13 different size drill bits for drilling the center holes because different pen styles require different diameter holes and some pens require a different size hole for each segment.

Step 4: Sand and then glue in Brass Tubes

Brass tubes are then glued into the holes drilled in the pen blanks. The tubes are sanded to rough up the surface and then pushed into the blank so they are inside the wood on each end. Pens have different length and diameter tubes that must be used based on the pen style.

Step 5: Trim and Clean Pen Blank

After the glue dries the blank is trimmed so the wood or acrylic ends are flush with the ends of the brass tubes.

Step 6: Hand Turn the Blank

The blank is mounted on the lathe and the design and crafting of the pen starts. The pen is hand turned from a rectangle blank to a rough shape of a pen using several different wood chisels. The pen is hand turned until the rough shape is slightly larger than the pen components.

Step 7: Sand the Pen Blanks

The pen blank is then sanded from 120 grit sand paper up to 800 grit sand paper.

Step 8: Apply Finish to the pen blanks

A finish is applied to the pen blank. Depending on the type of finish applied each pen gets 3 to 6 coats of finish.

Step 10: Buff the Pen Blank

A set of buffing wheels are installed on the lathe and the pen blanks are buffed prior to assembly.

Step 11: Assemble the Pen

The pen is then fully assembled with all of the components based on the pen style and the mechanical mechanisms tested for smooth operation.

Step 12: Wax and Polish

The pen is then waxed and polished and ran through another buffing step for the final finish.

Step 9: Sand Finished Pen blank

The pen blank is then sanded with micromesh sandpaper up to 12,000 grit